The Importance of Vacuum Leak Detector for Pharmaceutical Industries

Strict regulations require manufacturers to ensure the highest product and packaging standards. Companies set up comprehensive quality control measures, such as bottle leak detectors, to prevent the deterioration of the final product and their containers.

Maintaining product integrity requires a combination of storage solutions and effective package closure systems to prevent contamination, leakage of contents, and the consequences of both. Numerous leak detection methods allow manufacturers to meet quality regulations.

There are two main methods of effective bottle leak protection; pressure decay leak testing and vacuum leak detection. Pressure decay is the one that’s used the most in manufacturing since it is easily integrable into the production system. However, in this article, we’ll be talking about vacuum leak detection and how it can be useful to you depending on the characteristics of your production line.

What Is Vacuum Leak Detection?

First, we have to understand what a leak is. A leak is a small hole in one or more parts of a system that allows gas to enter or exit uncontrolled. Its rate depends on several factors, such as hole size, gas type, and pressure variance in the system. Detecting leaks in pressure and vacuum systems is important as they could evolve into more serious issues later down the road.

Unfortunately, they aren’t given the right amount of care at times. Despite these reasons, we must accept that a system can never be completely vacuum-tight. What is essential is that the operating pressure must be low enough for gas balance and capacity to maintain a deterministic pressure. There are several reasons why the system cannot maintain vacuum levels, including outgassing and contamination. Additionally, different processes and applications may have additional leak rate requirements.

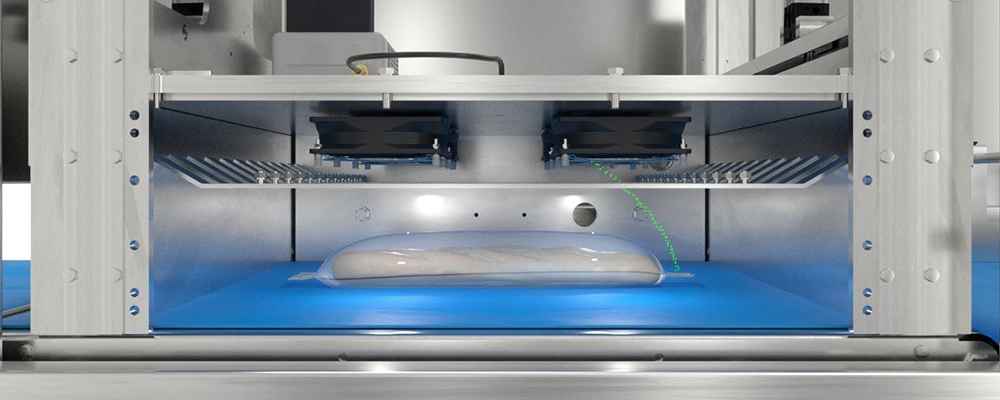

Vacuum leak detection involves a non-destructive test that detects leaks in flexible, rigid, or impermeable containers. This process is necessary to detect severe defects or leaks after the packing process is complete. This procedure places the sample in a closed vacuum chamber with an external vacuum source. Evacuation of the dead space of the test chamber follows and is done for a determined time using a selected target vacuum based on the sample under evaluation.

Consequently, the next step involves evaluating the increasing vacuum drop using absolute or differential pressure sensors for a timed period. A leak search occurs when the pressure increase exceeds the limit specified in the negative control. Using an effective seal-check for vacuum leak detection is an excellent way to notice this problem before it scales into the production line.

Features of Vacuum Leak Detection

Vacuum leak detection can bring a lot of pros into your manufacturing line if applied correctly. Below you’ll find a small list of benefits this testing procedure can bring to you:

- Ability to test in pressure or vacuum environments

- Flow rate calibration

- Reports loss of pressure or flow

- Simple and effective testing technique

- Determines leak rate regardless of pressure or flow

- Highly sensitive and can detect even the slightest leaks

The Necessity for Bottle Leak Protection

Now that we’ve identified the main ways to detect bottle leaks, let’s consider the importance of protecting packaging. It is to avoid causing damage. Integrating an effective bottle leak detector into your production line, combined with convenient mechanisms, will make your production line more reliable and improve your profit margins in the long run.

As a result, bottle leak detection complies with most manufacturers’ regulatory standards, improving your organization’s compliance with local laws. Testing bottles prior to distribution also ensures a quality product reaches the final consumer, increasing consumer confidence in the brand.

Final Remarks

Ultimately, the method chosen for a particular application depends on many factors, including instrument sensitivity, calibration, part variations, and the resources available. Functional testing helps ensure sealing and pressure maintenance of each bottle produced.

Testing is also necessary to avoid undetected quality issues during sampling. Therefore, functional testing improves the blow molding process, reduces overhead, and protects inventory. Integrating an effective bottle leak detector into your production line, combined with convenient mechanisms, will make your production line more reliable and improve your profit margins in the long run.